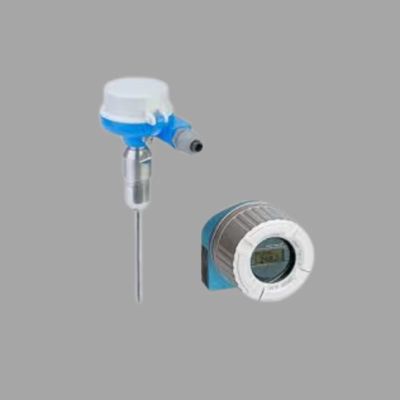

Endress+Hauser iTEMP TMT82 Sıcaklık Vericisi: Kapsamlı Teknik Genel Bakış

Endress+Hauser iTEMP TMT82, en zorlu endüstriyel uygulamalar için tamamen modüler, çift kanallı bir sıcaklık vericisi olarak tasarlanmış, sıcaklık ölçüm teknolojisinin zirvesini temsil eder. Bu gelişmiş cihaz, ölçüm doğruluğu, operasyonel güvenilirlik ve teşhis yeteneğinde yeni standartlar belirleyerek, sıcaklık ölçümünün güvenlik, kalite ve verimliliği doğrudan etkilediği kritik süreçler için ideal bir çözüm haline getirir. Geleceğe yönelik esneklikle tasarlanan TMT82, giriş, çıkış ve muhafaza konfigürasyonlarının tamamen özelleştirilmesine olanak tanıyan yenilikçi modüler tasarımı sayesinde neredeyse her türlü sıcaklık ölçüm senaryosuna uyum sağlar.

Gelişmiş Teknik Mimari ve Tasarım İnovasyonu

TMT82'nin olağanüstü performansının özünde, kullanıcıların özel uygulamaları için tam olarak gerekli konfigürasyonu belirlemelerini sağlayan devrim niteliğindeki modüler konsepti yatar. Verici, RTD'ler (Pt100, Pt1000, Ni100), termokupllar (Tip J, K, T, E, N, R, S, B, C), direnç sensörleri ve milivolt sinyalleri dahil olmak üzere kapsamlı bir sıcaklık sensörü yelpazesinden sinyalleri kabul edebilen iki bağımsız giriş kanalını destekler. Her kanal tamamen bağımsız olarak çalışır ve iki farklı proses noktasının eş zamanlı ölçümüne veya güvenlik enstrüman sistemleri (SIS) için gelişmiş oylama mantığı ile tek bir kritik noktanın yedekli ölçümüne olanak tanır. Cihaz, proses kesintisi olmadan ölçüm bütünlüğünü doğrulayan sürekli kendi kendini izleme ve doğrulama yetenekleri sağlayan Endress+Hauser'in tescilli Heartbeat Teknolojisini içerir. Bu teknoloji, proses kalitesini veya güvenliğini etkilemeden önce potansiyel sorunları tespit ederek tahmine dayalı bakım stratejilerini mümkün kılar.

TMT82'nin yapısı, en zorlu ortamlarda güvenilir çalışma sağlayan IP66/IP67 koruma derecesine sahip sağlam bir dökme alüminyum muhafaza ile endüstriyel dayanıklılığın bir örneğidir. Aşındırıcı atmosferler için paslanmaz çelik bir muhafaza seçeneği mevcuttur. Verici, Zone 1/21 tehlikeli alanlarda kullanım için ATEX, IECEx, FM ve CSA sertifikaları ile küresel patlama koruma gereksinimlerini karşılar. Yenilikçi terminal bölmesi tasarımı, elektronik modülün sökülmesine gerek kalmadan tam kablolamaya olanak tanıyarak kurulum süresini ve hata olasılığını önemli ölçüde azaltır. Geniş, yüksek kontrastlı LCD ekran, her iki ölçüm kanalının eş zamanlı okumasını ve kapsamlı durum bilgilerini sağlar ve herhangi bir kurulum yönünde optimum görüntüleme için 320° döndürülebilir.

Mükemmel Performans ve Uygulama Yetenekleri

TMT82, ölçülen değerin %±0,05'ine kadar doğruluk ve kalibrasyon gereksinimlerini en aza indiren uzun vadeli kararlılık ile olağanüstü ölçüm performansı sunar. Cihaz, hem geleneksel hem de tamamen dijital fieldbus mimarilerine sorunsuz entegrasyon sağlayan çift 4-20 mA HART sinyalleri, PROFIBUS PA, Foundation Fieldbus ve MODBUS RTU iletişimleri dahil olmak üzere çoklu çıkış seçenekleri sunar. Güçlü teşhis yetenekleri, kendi kendini izlemenin ötesine geçerek, her ölçülen kanal için ayrı alarm yanıtları ile kırılma, bozulma, kısa devreler ve konfigürasyon hatalarını tespit eden kapsamlı sensör teşhislerini içerir.

Bu verici, FDA uyumlu süreçler için doğrulanmış ölçüm sağladığı ilaç üretimi, reaktör sıcaklıklarını ve güvenlik döngülerini izlediği kimyasal işleme tesisleri, türbin sıcaklıklarını ve soğutma sistemlerini denetlediği enerji üretim tesisleri ve hassas termal işleme kontrolü sağladığı gıda ve içecek üretimi dahil olmak üzere çeşitli endüstrilerde uygulama alanı bulur. TMT82, özellikle yedekli sıcaklık ölçümü, sıcaklık farkı izleme veya IEC 61508'e göre SIL 2/3 sertifikası ile en yüksek güvenlik bütünlüğü seviyeleri gerektiren kritik uygulamalarda mükemmeldir.

| Bölüm |

Detaylar |

| Ürün Adı |

Endress+Hauser iTEMP TMT82 Sıcaklık Vericisi |

| Tip |

Tamamen modüler, çift kanallı sıcaklık vericisiAmaçKritik endüstriyel süreçler için yüksek doğrulukta, güvenilir ve özelleştirilebilir sıcaklık ölçümü |

| Temel Teknoloji |

- Özelleştirilebilir giriş, çıkış ve muhafaza için modüler konsept - Çift bağımsız giriş kanalı: iki noktayı ölçebilir veya oylama mantığı ile yedeklilik sağlayabilir (SIS) - RTD'leri (Pt100, Pt1000, Ni100), termokuplları (J, K, T, E, N, R, S, B, C), direnç sensörlerini, milivolt girişlerini destekler - Entegre Heartbeat Teknolojisi, sürekli kendi kendini izleme ve tahmine dayalı bakım için |

| Muhafaza ve Koruma |

- Dökme alüminyum muhafaza (IP66/IP67) - Aşındırıcı ortamlar için isteğe bağlı paslanmaz çelik muhafaza - Küresel patlama koruma sertifikaları: ATEX, IECEx, FM, CSA (Zone 1/21)Tasarım İnovasyonları- Terminal bölmesi, elektronik aksamı sökmeden kablolamaya izin verir - Geniş yüksek kontrastlı LCD ekran (eş zamanlı çift kanal ekran) - Esnek görüntüleme için 320° döndürülebilir ekranPerformans- Doğruluk: ölçülen değerin %±0,05'ine kadar - Uzun vadeli kararlılık, yeniden kalibrasyon ihtiyacını azaltır |

| Çıkışlar ve İletişim |

- Çift 4–20 mA HART sinyalleri - PROFIBUS PA - Foundation Fieldbus - MODBUS RTU |

| Teşhis |

- Heartbeat Teknolojisi (kendi kendini izleme ve doğrulama) - Sensör teşhisi: kırılma, bozulma, kısa devreler, konfigürasyon hatalarını tespit eder - Kanal başına ayrı alarmlar |

| Uygulama Alanları |

- İlaç: FDA uyumlu doğrulanmış süreçler - Kimya: Reaktör sıcaklıkları, güvenlik döngüleri - Enerji Üretimi: Türbin sıcaklığı, soğutma sistemleri - Gıda ve İçecek: Hassas termal işleme (pastörizasyon, sterilizasyon vb.) - Kritik Uygulamalar: Yedekli ölçüm, sıcaklık farkı izleme, SIL 2/3 sertifikalı (IEC 61508) |

| Operasyonel Verimlilik |

- ToF teknolojisi: muhafazayı açmadan konfigürasyon - Otomatik sensör tanıma ve konfigürasyon - FieldCare ve varlık yönetim sistemleri ile sorunsuz entegrasyon - Parametrelerin uzaktan izlenmesi ve belgelenmesi |

| Temel Avantajlar |

- Çift kanallı esneklik - Yüksek doğruluk ve güvenilirlik - Zorlu ortamlar için sağlam muhafaza - Tehlikeli alanlar için sertifikalı (SIL 2/3) - Heartbeat Teknolojisi ile tahmine dayalı bakım - Devreye alma ve yaşam döngüsü maliyetlerini azaltır |

| Özet |

TMT82, modüler esneklik, yedekli yetenek ve gelişmiş teşhisleri birleştirerek proses güvenliğini, güvenilirliğini ve verimliliğini en üst düzeye çıkarmak için akıllı sıcaklık ölçümünde yeni bir ölçüt belirler.Operasyonel Verimlilik ve Yaşam Döngüsü YönetimiTMT82, muhafazayı açmadan konfigürasyona olanak tanıyan Endress+Hauser'in ToF (Tool-operated Fieldbus) teknolojisini kullanarak sezgisel parametrelendirmesi sayesinde olağanüstü operasyonel verimlilik gösterir ve böylece tehlikeli alanlardaki koruma derecesinin bütünlüğünü korur. Cihaz, otomatik sensör tanıma ve konfigürasyonunu destekleyerek devreye alma süresini ve hata olasılığını önemli ölçüde azaltır. Gelişmiş yönetim için, verici, Endress+Hauser'in FieldCare ve diğer varlık yönetim sistemleriyle sorunsuz bir şekilde entegre olarak, cihaz parametrelerinin operasyonel yaşam döngüsü boyunca uzaktan izlenmesini, yapılandırılmasını ve belgelenmesini sağlar.Eşsiz esnekliği, çift kanallı yeteneği ve gelişmiş teşhis özellikleri ile iTEMP TMT82, akıllı sıcaklık ölçümü için yeni bir ölçüt oluşturarak, kullanıcılarına benzeri görülmemiş güvenilirlik, güvenlik ve operasyonel verimlilik sağlarken, azaltılmış bakım gereksinimleri ve uzatılmış kalibrasyon aralıkları sayesinde toplam sahip olma maliyetini düşürür.Lütfen Sean ile 13032169980 numaralı telefondan iletişime geçinŞirket web sitesi: https://shanghaixiangjing.gys.cn/company-information.html |

|

|

|

|

|

|

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!

Genel Değerlendirme

Derecelendirme Anlık Görüntüsü

Aşağıdaki tüm oyların dağılımıdırTüm Yorumlar