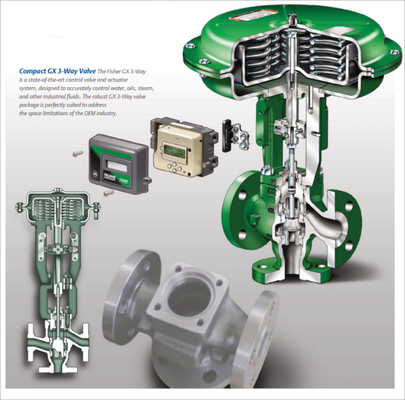

Ürün Tanımı:

Fisher Kontrol Valfleri

Bir yüzyıldan fazla bir süredir, Fisher Kontrol Valfleri, müşteri beklentilerini aşan üstün kalite kontrol valf çözümleri sunmakla ünlüdür.Fisher Kontrol Valfleri endüstride güvenilirlik ve yenilikçilik için bir üne sahip..

Bu valfler, petrol, gaz, kimyasal ve elektrik enerjisi dahil olmak üzere çeşitli endüstriyel alanlarda yaygın olarak kullanılmaktadır.Güvenilir ve tutarlı performansları onları kritik uygulamalar için ideal bir seçim haline getirir.

Özellikleri:

Dinamik istikrar ve frekans tepkisi söz konusu olduğunda, Fisher kontrol valfi gerçekten parlıyor.Daha küçük bir oda hacmi oluşturarak yanıt süresini azaltabilirBu tasarım elemanları, Fisher kontrol valfinin çeşitli çalışma koşullarında hızlı bir şekilde yanıt vermesini sağlar.

Fisher kontrol valfinin bir diğer önemli özelliği, yüksek itiş gücüne dayanabilmesidir.Valf aynı zamanda güçlü özellikleri, kalın duvarlı dökme demir ve çelik yapısı, mükemmel bir istikrar ve korozyon direnci sunar. Bu tasarım, vananın aşırı basınç koşullarında bile deformasyonun devam etmesine yardımcı olur.hizmet ömrünü uzatmak.

Fisher kontrol valfinin gerçekten öne çıktığı bir alan düşük sıcaklık koşullarına uygun olmasıdır.Tüm boyutlardaki 657 ve 667 diyafram aktüatörleri, -50°C'ye kadar düşük sıcaklıklarda kullanılmak üzere tasarlanmış geliştirilmiş ürün özelliklerinde mevcuttur.Bununla birlikte, aktüatörün -40°C'nin altındaki sıcaklıklarda tepki vermesini sağlamak için bir konumlandırıcının önerildiğini belirtmek önemlidir.

Son olarak, Fisher kontrol valfi, bir sıkıştırma sapı bağlantısı ile tasarlanmıştır. Bu tasarım unsuru, güvenilir hareket teslimatı ve kolay montajı sağlar.Bu tasarım sorunlu bağlantı boşluklarını ve diğer ürünlerle sorunlara neden olabilecek yanlış valf konumlandırmasını önler.

Dinamik istikrar ve frekans tepkisi söz konusu olduğunda, Fisher kontrol valfi gerçekten parlıyor.Daha küçük bir oda hacmi oluşturarak yanıt süresini azaltabilirBu tasarım elemanları, Fisher kontrol valfinin çeşitli çalışma koşullarında hızlı bir şekilde yanıt vermesini sağlar.

Fisher kontrol valfinin bir diğer önemli özelliği, yüksek itiş gücüne dayanabilmesidir.Valf aynı zamanda güçlü özellikleri, kalın duvarlı dökme demir ve çelik yapısı, mükemmel bir istikrar ve korozyon direnci sunar. Bu tasarım, vananın aşırı basınç koşullarında bile deformasyonun devam etmesine yardımcı olur.hizmet ömrünü uzatmak.

Fisher kontrol valfinin gerçekten öne çıktığı bir alan düşük sıcaklık koşullarına uygun olmasıdır.Tüm boyutlardaki 657 ve 667 diyafram aktüatörleri, -50°C'ye kadar düşük sıcaklıklarda kullanılmak üzere tasarlanmış geliştirilmiş ürün özelliklerinde mevcuttur.Bununla birlikte, aktüatörün -40°C'nin altındaki sıcaklıklarda tepki vermesini sağlamak için bir konumlandırıcının önerildiğini belirtmek önemlidir.

Son olarak, Fisher kontrol valfi, bir sıkıştırma sapı bağlantısı ile tasarlanmıştır. Bu tasarım unsuru, güvenilir hareket teslimatı ve kolay montajı sağlar.Bu tasarım sorunlu bağlantı boşluklarını ve diğer ürünlerle sorunlara neden olabilecek yanlış valf konumlandırmasını önler.

Teknik parametreler:

| Teknik parametreler |

Değer |

| Uygulama Senaryosu |

Su, Buhar, Gaz vb. |

| Sertifikalar |

PED, CUTR, ATEX, CRN |

| Çıktı Karakteristiği |

Doğruluk |

| Gaz temini basınç aralığı |

140 ila 700 KPa |

| Kontrol sinyali |

4-20 MA |

| Çalışma sıcaklığı |

Standart sıcaklık |

| Garanti Dönemi |

1 yıl |

| Valf Boyutu |

NPS 1, NPS 2 |

| Akış Özellikleri |

Eşit Yüzde |

| Kritik Hizmet |

Kirli Hizmet, Erozif |

Uygulamalar:

Fisher kontrol valfleri, neredeyse her kontrol valfi uygulamasına uygun olarak tasarlanmıştır ve kapsamlı bir aküatör türü ve boyutu vardır.Bu esneklik, valflerin çeşitli endüstrilerde ve uygulamalarda kullanılmasını sağlar, petrol ve gaz, enerji üretimi ve kimyasal işleme dahil olmak üzere.

Dahası, Fisher, kullanıcıların özel ihtiyaçlarına göre valfleri daha da özelleştirmelerini sağlayan bir dizi yay sertlik seçeneği, seyahat sınırlayıcıları ve manuel cihazlar sunar.Düşük basınçlı veya yüksek basınçlı bir uygulama olsunFisher'ın işi halledebilecek bir valfi var.

Çok çeşitli seçenekler arasından seçim yapabilmek, Fisher kontrol valflerinin kullanıcının uygulamasının özel gereksinimlerini karşılamak için uyarlanabilmesi anlamına gelir.Daha hassas bir kontrol ve daha iyi genel performans sağlar.

Destek ve Hizmetler:

Pnömatik Kontrol Valfi ürünün teknik desteği ve hizmetleri şunları içerir:

- Kurulum desteği ve rehberlik

- Ürün sorun giderme ve sorun çözme

- Onarım ve bakım hizmetleri

- Ürün belgeleri ve kullanım kılavuzları

- Ürün eğitimi ve eğitimi

- Özel uygulamalar için özel çözümler

Our team of experts is dedicated to providing excellent customer service and ensuring that our customers have the knowledge and resources necessary to maximize the performance and longevity of their Pneumatic Control Valve product.

Ambalaj ve Nakliye:

Ürün ambalajı:

Pnömatik Kontrol Valf ürünü güvenli taşımacılığı sağlamak için güvenli bir şekilde paketlenmelidir.Valf, nakliye sırasında herhangi bir hasarı önlemek için bolca dolgu ile sağlam bir karton kutuya yerleştirilecektir.

Nakliye:

Pnömatik Kontrol Valf ürünü güvenilir ve verimli bir taşıyıcı hizmeti ile gönderilecektir. Nakliye maliyeti, paketin varış noktasına ve ağırlığına göre hesaplanacaktır.Siparişi aldıktan sonra 1-2 iş günü içinde ürünü göndermeyi hedefliyoruz., ve teslimat süresi varış noktasına bağlı olacaktır.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!

Genel Değerlendirme

Derecelendirme Anlık Görüntüsü

Aşağıdaki tüm oyların dağılımıdırTüm Yorumlar